Modified Bitumen Roofing Systems

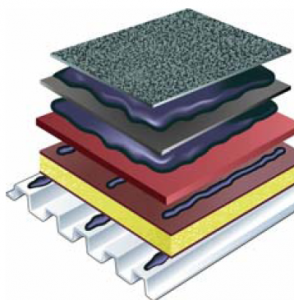

Modified bitumen roof membranes are made from either APP (plastic) or SBS (rubber) modified asphalt with polyester and/or fiberglass reinforcement scrims. The Modified Bitumen Roof Membrane can be installed torch applied, where the back of the sheet is heated with an open flame and welded to the base ply, hot applied with hot asphalt or fully adhered with a cold adhesive. The Modified Bitumen Roof Membrane comes with a granulated surface in various colors or smooth surfaced-usually finished with an aluminum reflective coating. Modified Bitumen Roof Membrane are used as cap sheets with the built-up roof systems as well.

In Europe, where modified membranes were first introduced, they were installed with a two ply application method. The American manufacturers specified a single ply application to be competitive with others roof systems and performance has been mixed depending on attention to detail in the installation and application conditions such as roof slope, ponding and runoff restrictions. More stringent requirements addressing these conditions have been implemented in recent years and more manufacturers and roofing companies are specifying multiple ply applications with the Modified Bitumen Roof Membrane.

The Modified Bitumen materials make an excellent roof with the right application specifications and sufficient attention to detail. Click here for technical information.

For more information please call our roofing professionals at (303) 971-0256 or Click Here to request a free quote.