Your chimney represents one of your home's most vulnerable points for water infiltration and weather damage, making proper chimney topper and cap protection absolutely essential for Denver area properties. At Calebs Management Enterprises, we've dedicated over 40 years to perfecting our custom chimney topper fabrication services, creating precision metalwork that protects your chimney system while enhancing your home's architectural appeal.

As Colorado's premier custom metal fabrication company, we understand that every chimney presents unique challenges requiring custom-designed solutions. Our chimney toppers and caps are individually fabricated to match your specific chimney dimensions, architectural style, and performance requirements. With our BBB A+ rating and membership in the Colorado Roofing Association, we bring professional expertise and craftsmanship excellence to every chimney protection project.

Our 48-hour turnaround capability on most metal fabrication orders means you don't have to wait weeks for the custom chimney protection your home needs. Whether you're planning preventive protection for your chimney system or need replacement components, our rapid fabrication capabilities ensure your project moves forward efficiently and on schedule.

What distinguishes our chimney topper fabrication is our deep understanding of Colorado's unique climate challenges. Our 40+ years of experience has taught us how altitude, temperature extremes, and seasonal weather patterns affect different chimney configurations and materials. This knowledge enables us to design and fabricate chimney protection systems that perform reliably year after year in Denver's demanding environment.

Ready to protect your chimney with custom fabricated solutions designed for Colorado's demanding conditions? Visit our contact page to schedule your comprehensive consultation.

Colorado's climate presents unique challenges for chimney systems that require specialized protection solutions. Our 40+ years of experience fabricating chimney toppers and caps has taught us how altitude, temperature extremes, and seasonal weather patterns affect different chimney configurations and materials throughout Denver, CO and surrounding communities.

Freeze-thaw cycles represent one of the most destructive forces affecting Denver area chimneys, creating tremendous pressure that can crack mortar joints and damage brick.

When moisture penetrates chimney masonry and freezes, the expanding ice creates tremendous pressure that can crack mortar joints, damage brick, and compromise structural integrity. Our custom fabricated chimney toppers create complete weather barriers that prevent moisture infiltration while allowing proper ventilation for safe operation.

Our designs specifically address these freeze-thaw challenges with comprehensive coverage and proper drainage features that keep moisture away from vulnerable masonry surfaces.

Denver's elevation and geography create weather patterns that can drive rain and snow horizontally, forcing moisture into chimney openings that standard caps cannot protect.

Wind-driven precipitation poses a significant challenge for exposed chimney systems. Our fabrication approach addresses these unique weather patterns with custom-designed overhang dimensions and specialized drainage features that prevent moisture infiltration even during severe weather events.

We analyze prevailing wind patterns and chimney exposure to determine optimal overhang dimensions and protective features that keep your chimney system dry regardless of weather conditions.

UV exposure at Colorado's altitude accelerates deterioration of many standard chimney cap materials and finishes, requiring specialized material selection.

Our material selection and finishing processes account for intense UV conditions, ensuring long-term performance and appearance retention. We select metals and protective coatings that withstand Colorado's high-altitude environmental conditions without premature aging or failure.

Thermal cycling from extreme temperature variations requires chimney protection systems that accommodate expansion and contraction without cracking or loosening. Our fabrication techniques include appropriate provisions for thermal movement while maintaining weathertight seals, preventing the premature failures common with inadequately designed chimney protection systems.

Every custom chimney cap begins with detailed field measurements and analysis of your specific chimney configuration. Our initial assessment establishes the foundation for effective chimney cap design by documenting chimney dimensions, flue configurations, existing damper systems, and architectural details that influence our fabrication approach.

This comprehensive assessment ensures our custom fabricated caps integrate perfectly with existing systems while providing optimal protection. We take the time to understand both the functional requirements and aesthetic objectives of your chimney protection project.

Our design development process incorporates both functional requirements and aesthetic objectives into comprehensive fabrication plans. We create detailed drawings that specify dimensions, materials, ventilation provisions, and installation details. Our design process accounts for local building codes, fire safety requirements, and manufacturer specifications for chimney system components.

Material selection for chimney cap fabrication depends on performance requirements, architectural compatibility, and budget considerations. We fabricate chimney caps using galvanized steel, stainless steel, copper, and aluminum, selecting materials based on durability requirements and visual objectives. Our material expertise ensures appropriate choices for Colorado's demanding environmental conditions.

Our forming and fabrication operations transform raw materials into precision chimney caps using specialized metalworking techniques. We use custom forming dies and hand-forming methods to create complex geometries while maintaining consistent dimensions and professional appearances. Our fabrication process includes provisions for mounting hardware, ventilation features, and drainage requirements.

Chimney toppers represent more complex fabrication challenges than simple chimney caps, requiring engineering expertise to create systems that protect multiple flues while accommodating various chimney configurations. We design and fabricate toppers that accommodate different flue sizes and heights within the same chimney structure, ensuring each flue maintains optimal performance while sharing common weather protection.

Structural design becomes critical for large chimney topper installations that must withstand Colorado's wind loads and snow accumulation. We calculate structural requirements based on topper dimensions, material specifications, and local weather conditions. Our structural approach ensures long-term stability while maintaining proper chimney system operation.

Ventilation engineering ensures chimney toppers provide effective weather protection without compromising draft performance or creating dangerous backdraft conditions. We design ventilation openings and airflow patterns that maintain proper chimney operation while excluding wind-driven precipitation. This engineering balance prevents both weather damage and operational problems.

Note: Calebs installs many roofing systems; the manufacturers shown are those for which Calebs holds certified installer status and can provide a No Dollar Limit (NDL) warranty.

The selection of appropriate materials for chimney topper and cap fabrication significantly impacts long-term performance and maintenance requirements. Our 40+ years of experience with chimney protection systems has taught us which materials provide optimal durability in Colorado's challenging climate while maintaining their aesthetic appeal over decades of service.

Our premium material choice for applications requiring maximum durability and minimal maintenance. Stainless steel provides exceptional corrosion resistance while maintaining strength characteristics essential for wind and snow loading.

Offers traditional appeal with natural weather resistance that improves over time. Copper chimney caps and toppers develop protective patina that enhances corrosion resistance while creating distinctive visual character.

Provides excellent value for many chimney protection applications, offering reliable performance at moderate cost. We select high-quality galvanized materials with appropriate coating specifications for chimney environments.

Appropriate for situations where weight considerations or specific architectural requirements favor lightweight materials. We fabricate aluminum chimney protection using alloys selected for strength and corrosion resistance.

Our coating and finishing selection significantly impacts the longevity and appearance of fabricated chimney protection systems. We apply protective coatings based on material types, environmental exposure, and aesthetic requirements to ensure optimal performance in Denver's challenging climate.

The installation of custom fabricated chimney toppers and caps requires specialized expertise that goes beyond standard roofing techniques. Our installation teams combine safety protocols with precision fitting methods, ensuring every custom fabricated piece performs exactly as designed.

We implement comprehensive fall protection systems and use specialized equipment designed for steep roof and chimney access. Our safety protocols exceed OSHA requirements and reflect our commitment to zero-accident performance on every project.

Our installation teams use specialized measuring tools and fitting methods to achieve tight tolerances and professional appearances. Our approach accounts for thermal expansion, wind loading, and long-term performance requirements.

We use appropriate sealants and flashing techniques to create weathertight connections between toppers and existing chimney systems. Our sealing methods accommodate thermal movement while maintaining long-term effectiveness.

Proper maintenance significantly extends the service life of custom fabricated chimney toppers and caps while preserving their protective effectiveness. Our comprehensive maintenance programs help you protect your investment while preventing costly problems.

When Denver area homeowners need custom chimney topper and cap fabrication, they consistently choose Calebs Management Enterprises because of our unique combination of metalworking expertise, chimney system knowledge, and customer service excellence. Our 40+ years in business has established us as Colorado's premier custom metal fabrication company for chimney protection applications.

Our BBB A+ rating demonstrates consistent customer satisfaction and project excellence across hundreds of chimney protection installations. This rating represents our commitment to delivering technical expertise with professional service standards.

Our 48-hour turnaround capability on most metal fabrication orders provides efficient service while accommodating planned installation schedules. This fabrication efficiency sets us apart from competitors who require weeks for custom work.

Our local expertise and understanding of Colorado conditions influence every aspect of our fabrication and installation processes. We understand how altitude, weather patterns, and environmental factors affect chimney protection system performance.

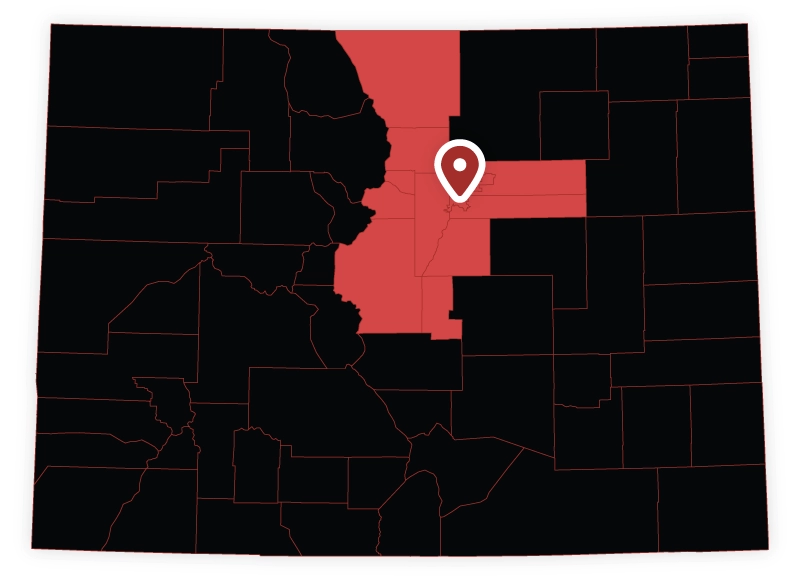

Calebs Management Enterprises proudly serves homeowners throughout the Denver metropolitan area and surrounding Colorado communities with custom chimney topper and cap fabrication services. Our strategic Denver location allows us to respond quickly to service calls while maintaining the fabrication capabilities necessary for complex custom metalwork projects.

Our standard fabrication turnaround is 48 hours for most chimney topper and cap projects, significantly faster than industry averages. Complex multi-flue systems or projects requiring extensive custom forming may require additional time, but we provide accurate timelines during initial consultation. We prioritize efficient scheduling to meet your project timeline requirements.

Material selection depends on performance requirements, budget considerations, and aesthetic objectives. Stainless steel provides maximum durability with minimal maintenance requirements. Copper offers traditional appeal with natural weather resistance that improves over time. Galvanized steel provides excellent value for most applications. We recommend materials based on your specific requirements and environmental exposure.

Properly designed chimney toppers enhance rather than compromise chimney system performance. Our engineering approach ensures adequate ventilation while providing weather protection. We design toppers that maintain proper draft characteristics while preventing downdrafts and weather infiltration. Improper topper design can create problems, which is why professional fabrication and installation are essential.

Yes, our custom fabrication capabilities allow us to address virtually any chimney configuration or architectural challenge. Whether your chimney features multiple flues, unusual dimensions, or complex geometries, we can create effective protection solutions. Our 40+ years of experience with diverse chimney applications enables us to tackle the most challenging requirements.

Building code requirements vary based on local jurisdictions and chimney system types. We ensure all our fabrication and installation work meets applicable codes and standards. When permits are required, we assist with application processes and coordinate with local building departments. Our experience with code requirements streamlines the approval process.

We provide comprehensive warranty coverage for both fabrication quality and installation workmanship, with terms that vary based on materials and application requirements. Our warranty process includes prompt response to any issues and complete documentation of repairs or replacements. Our BBB A+ rating demonstrates our commitment to honoring warranty obligations.

We recommend annual inspection of chimney toppers and caps, ideally as part of a comprehensive chimney maintenance program. More frequent inspections may be necessary following severe weather events or if you notice any changes in chimney performance. Our inspection services identify potential issues before they compromise chimney protection or create safety hazards.

Warning signs include visible rust or corrosion, loose or missing components, water staining on interior walls near the chimney, deteriorating mortar joints, or evidence of animal intrusion. If you notice changes in draft performance or smoke backing up into your home, these may also indicate chimney cap issues that require professional attention.

We sincerely appreciate your business and the trust you've placed in us for your roofing and custom metal fabrication needs. We believe the highest compliment is a referral, and our Customer Referral Program is our way of saying thank you for sharing your positive experience with friends, family, and neighbors.

Refer a friend, family member, or neighbor to Calebs, and you'll earn a reward when they complete a new roofing or metal fabrication project.

Once their project is successfully completed, you'll be able to choose from a selection of great reward options as our thank you for your referral.

Our program offers increasing rewards based on the number of successful referrals you make. The more you refer, the more you earn!

Your referrals are important to us and truly help us continue to grow our over 40-year legacy so we can serve the Colorado community with excellence!

When you choose Calebs Management Enterprises, Inc., you're selecting a contractor with 40+ years of proven expertise throughout Denver, Colorado. Our custom chimney topper and cap fabrication services provide the complete solution for property owners who demand both quality and reliability.

Our BBB A+ rating, Colorado Roofing Association membership, and unique 48-hour turnaround capability on custom metal fabrication deliver responsive service and superior craftsmanship. Ready to protect your chimney with Denver's most trusted metal fabrication expertise? Contact us today.