Effective sheet metal flashing represents the most critical component in protecting your Denver home from water damage, yet it's often the most overlooked aspect of roofing systems. At Calebs Management Enterprises, we've dedicated over 40 years to mastering the art and science of custom sheet metal flashing fabrication, creating precision metalwork that safeguards your home's most vulnerable areas from Colorado's challenging weather conditions.

As Colorado's premier custom metal fabrication company, we understand that proper flashing isn't just about directing water – it's about creating integrated protection systems that work seamlessly with your roofing materials while accommodating thermal movement, structural settling, and the extreme weather variations that define Colorado's climate. Our BBB A+ rating and membership in the Colorado Roofing Association reflect our commitment to delivering flashing solutions that provide decades of reliable protection.

Sheet metal flashing serves as your home's primary defense against water infiltration at every roof intersection, penetration, and transition point. Our 40+ years of fabricating custom flashing systems has taught us that successful water management requires understanding how moisture behaves around complex roof geometries and designing metalwork that directs water flow while accommodating the structural and thermal movements that occur in real-world applications.

Roof-to-wall intersections represent some of the most challenging flashing applications, requiring step flashing systems that integrate with both roofing materials and metal siding systems. We fabricate custom step flashing that follows roof slopes while maintaining proper overlap with wall coverings. Our fabrication techniques ensure water cannot penetrate behind step flashing while accommodating the thermal expansion that occurs at these critical intersections.

Our 48-hour turnaround capability on most metal flashing orders ensures your roofing project maintains momentum without weather-related delays. Whether you're planning comprehensive roof replacement or need custom replacement components for ongoing maintenance, our rapid fabrication capabilities provide the custom flashing components your project demands when you need them most.

Ready to protect your property with precision-fabricated sheet metal flashing? Visit our contact page to schedule your comprehensive consultation.

Drip edge fabrication represents one of our most frequently requested services, yet many homeowners don't realize the critical role properly fabricated drip edges play in protecting their home's structural components. Our custom drip edge fabrication process creates precision components that not only direct water effectively but also enhance your roof's professional appearance while providing long-term protection for fascia boards and soffit systems.

Design analysis for custom drip edge fabrication begins with understanding your specific roof configuration, gutter system, and architectural requirements.

We evaluate roof slope, fascia board dimensions, gutter placement, and aesthetic objectives to design drip edges that optimize performance while complementing your home's visual appeal. Our design approach ensures proper water flow while preventing the backup conditions that can cause fascia damage.

Our comprehensive analysis includes consideration of local weather patterns, exposure conditions, and architectural style to create drip edge solutions that provide both functional excellence and visual integration with your property's design elements.

Material selection for drip edge fabrication depends on durability requirements, architectural compatibility, and environmental exposure conditions.

We fabricate drip edges using galvanized steel, aluminum, and copper, selecting materials based on your specific performance requirements and budget considerations. Our material expertise ensures appropriate gauge selections and finish specifications for Colorado's demanding climate.

Each material offers distinct advantages: galvanized steel provides excellent value and durability, aluminum offers lightweight corrosion resistance, while copper delivers premium aesthetics with exceptional longevity. We help you select the optimal material for your specific application.

Forming operations for custom drip edges require precision equipment and experienced craftsmen to achieve consistent dimensions and professional appearances.

We use specialized forming dies and careful quality control to create drip edges that install easily while providing optimal performance. Our forming techniques accommodate various roof slopes and gutter configurations.

Our advanced metalworking equipment allows us to maintain tight tolerances and consistent bends across production runs, ensuring your drip edge components fit perfectly during installation while providing the precise water management characteristics your roof requires.

Valley flashing fabrication requires sophisticated engineering expertise to create systems that handle concentrated water flow while integrating effectively with roofing materials and structural components. Our valley flashing designs combine hydraulic engineering principles with precision metalworking to create protection systems that prevent the water damage and ice formation problems common in Colorado's challenging climate.

Hydraulic design considerations form the foundation of effective valley flashing systems. We calculate water flow volumes based on roof areas, slope configurations, and expected precipitation rates to design valleys with appropriate capacity for Colorado weather conditions. Our hydraulic analysis ensures valleys can handle extreme weather events without overflow or backup conditions.

Structural integration requirements demand that valley flashing systems connect securely to roof decking while accommodating thermal movement and structural settling. We design mounting systems and fastening details that provide long-term security without creating stress concentrations or leak points. Our structural approach ensures valley systems remain secure under wind and snow loading.

Custom forming techniques for valley flashing accommodate various roof slopes and intersections while maintaining optimal water flow characteristics. We fabricate valleys with appropriate slope transitions and drainage features that prevent debris accumulation and ice formation. Our forming expertise creates smooth water flow surfaces that minimize maintenance requirements.

Thermal expansion provisions prevent stress-related failures in valley flashing subjected to Colorado's extreme temperature variations. We include expansion joints and flexible connections that accommodate thermal movement without compromising water integrity. This attention to thermal considerations ensures long-term performance without maintenance-intensive adjustments.

Complex roof intersections where multiple planes, materials, and penetrations converge represent the most challenging flashing applications in residential construction. Our expertise in fabricating custom flashing solutions for these complex situations has developed through decades of solving unique water management problems that standard flashing products cannot address effectively.

Penetration integration around chimneys, skylights, and mechanical equipment demands precision fabrication and careful attention to sealing details. We create custom flashing systems that conform to irregular shapes while providing complete weather protection. Our penetration flashing designs include provisions for maintenance access and equipment removal when necessary.

Material transition flashing between different roofing systems requires engineering expertise to create compatible connections that accommodate different thermal characteristics. We fabricate transition systems that maintain water integrity while allowing necessary differential movement between materials. Our transition solutions work effectively with all common roofing material combinations.

Note: Calebs installs many roofing systems; the manufacturers shown are those for which Calebs holds certified installer status and can provide a No Dollar Limit (NDL) warranty.

The selection of appropriate materials for sheet metal flashing fabrication significantly impacts long-term performance, maintenance requirements, and overall system reliability. Our extensive experience with different materials in Colorado's challenging environment enables us to recommend optimal material choices that balance performance requirements with cost considerations and architectural compatibility.

Galvanized steel represents our most frequently specified material for residential flashing applications, offering excellent durability at moderate cost. We use high-quality galvanized steel with appropriate coating specifications for Colorado's environmental conditions.

Stainless steel provides premium performance for applications requiring maximum durability and minimal maintenance. We fabricate stainless steel flashing systems using appropriate alloy selections for corrosion resistance and structural requirements.

Aluminum fabrication offers lightweight solutions with excellent corrosion resistance for many flashing applications. We select aluminum alloys based on strength requirements and environmental exposure conditions.

Copper flashing provides traditional appeal with natural weather resistance that improves over time through patina development. We fabricate copper flashing systems using appropriate gauges and forming techniques that prevent stress cracking.

Our material selection approach prevents the problems that develop when incompatible materials are used together, ensuring your flashing system provides optimal performance throughout its service life in Denver's challenging climate conditions.

Our sheet metal flashing fabrication process combines advanced equipment with skilled craftsmanship to create precision components that meet exacting tolerances and performance requirements. Every fabricated piece undergoes comprehensive quality control procedures that ensure consistent results and reliable long-term performance for your roofing protection systems.

We create detailed templates based on field measurements and engineering specifications, ensuring consistent dimensions across multiple fabrication pieces. Our template development process includes provisions for material thickness, bend allowances, and assembly tolerances.

We inspect raw materials for quality and prepare surfaces for forming operations. Our material preparation includes cleaning, marking, and staging operations that facilitate efficient fabrication while maintaining quality standards.

We use brake presses, roll formers, and custom dies to achieve consistent dimensions and professional appearances. Our forming techniques accommodate various material types while maintaining dimensional accuracy.

We use appropriate soldering, welding, and mechanical joining methods based on material types and performance requirements. Our joining expertise ensures watertight connections that withstand environmental exposure and structural movement.

We apply appropriate protective finishes and edge treatments that prevent corrosion while maintaining visual appeal. Our finishing processes account for environmental exposure and maintenance accessibility requirements.

We conduct dimensional checks, visual inspections, and functional testing when appropriate. Our quality control documentation provides verification of compliance with specifications and performance requirements.

Proper installation of custom fabricated sheet metal flashing requires technical expertise and attention to detail that goes beyond standard roofing practices. Our comprehensive installation support services ensure your custom flashing components perform exactly as designed while providing the technical guidance necessary for optimal long-term results.

We provide installation sequences and technical guidance that prevent conflicts and ensure optimal performance. Our planning approach accounts for weather dependencies, material handling requirements, and safety considerations.

We develop comprehensive specifications that address fastening requirements, sealing methods, and integration details. Our technical documentation ensures consistent installation results regardless of contractor experience levels.

Our technical representatives can provide installation guidance and troubleshooting support when projects encounter unexpected challenges. This field support ensures optimal results for even the most demanding installations.

We provide inspection checklists and testing protocols that verify installation quality. Our verification approach ensures flashing systems perform as intended from the first day of service.

We provide technical training on proper installation methods and best practices for sheet metal flashing systems. Our training approach improves installation quality while reducing callbacks and warranty issues.

We provide warranty coverage for both fabrication quality and installation when performed according to our specifications. Our warranty support includes repair and replacement services when issues develop.

When Denver area contractors and homeowners need custom sheet metal flashing fabrication, they consistently choose Calebs Management Enterprises because of our unique combination of metalworking expertise, engineering knowledge, and customer service excellence. Our 40+ years in business has established us as Colorado's premier custom metal fabrication company for the most demanding flashing applications.

Our BBB A+ rating demonstrates consistent customer satisfaction and project excellence across thousands of flashing fabrication projects. This rating represents our commitment to delivering technical expertise with professional service standards.

Colorado Roofing Association membership keeps us current with industry standards, code requirements, and best practices for flashing applications. This professional affiliation demonstrates our commitment to continuing education and industry leadership.

Our 48-hour turnaround capability on most metal flashing orders provides the rapid response that weather-sensitive projects demand. This fabrication efficiency sets us apart from competitors who require weeks for custom work.

Our combination of traditional metalworking skills and modern fabrication equipment creates solutions that other fabricators cannot match. When your project presents unique challenges, our capabilities deliver effective solutions.

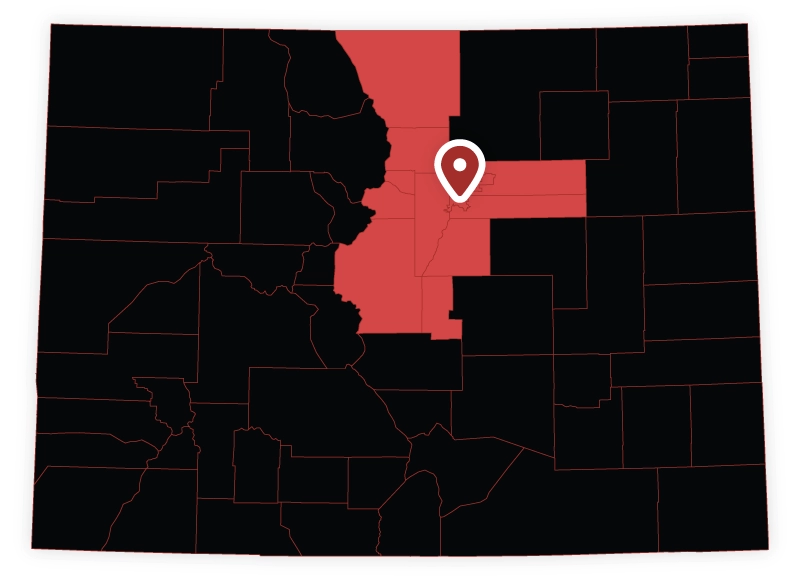

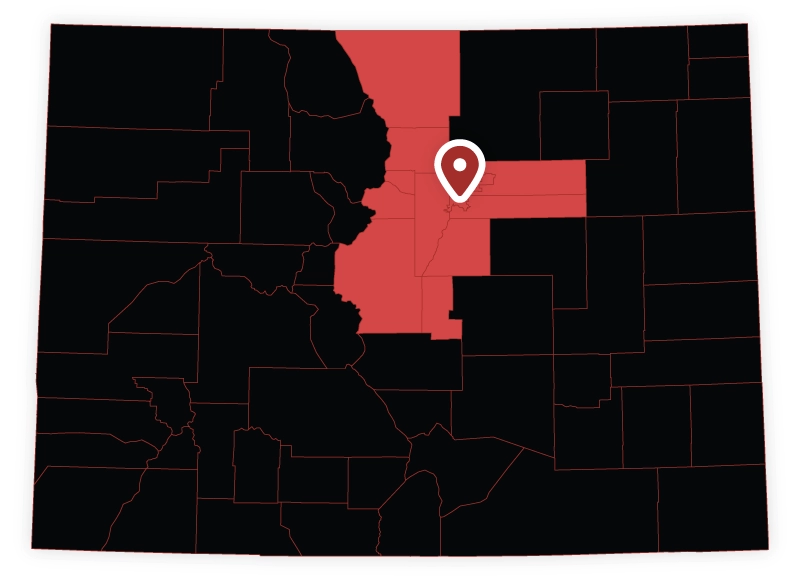

Calebs Management Enterprises proudly serves contractors and homeowners throughout the Denver metropolitan area and surrounding Colorado communities with custom sheet metal flashing fabrication services. Our strategic Denver location allows us to respond quickly to urgent fabrication needs while maintaining the manufacturing capabilities necessary for large-scale projects.

Our extensive service area coverage ensures prompt response times and efficient project execution throughout the Denver metro region. We understand the unique environmental conditions and architectural styles present in different communities, allowing us to tailor our fabrication approaches for optimal performance in your specific location.

Our standard fabrication turnaround is 48 hours for most sheet metal flashing projects, significantly faster than industry averages. Complex multi-component systems or projects requiring extensive custom forming may require additional time, but we provide accurate timelines during initial consultation. We prioritize efficient scheduling to meet your project timeline requirements.

Material selection depends on application requirements, budget considerations, and aesthetic objectives. Galvanized steel provides excellent value with reliable performance for most applications. Stainless steel offers maximum durability for demanding environments. Aluminum provides lightweight solutions with good corrosion resistance. Copper offers traditional appeal with exceptional longevity. We recommend materials based on your specific requirements.

Yes, our custom fabrication capabilities allow us to address virtually any roof configuration or architectural challenge. Whether your project involves complex intersections, unusual slopes, or unique penetrations, we can create effective flashing solutions. Our 40+ years of experience with diverse applications enables us to tackle the most challenging requirements with confidence.

We provide comprehensive technical support including installation specifications, field assistance, and quality verification services. While we primarily focus on fabrication, our technical team can provide installation guidance and troubleshooting support to ensure optimal results. We work closely with qualified contractors to ensure proper installation.

We maintain rigorous quality control procedures throughout our fabrication process, from material inspection through final testing. Our quality standards exceed industry requirements and reflect our BBB A+ rating. We provide detailed quality documentation and testing verification for all fabricated components.

We provide comprehensive warranty coverage for fabrication quality, with terms that vary based on materials and application requirements. Our warranty includes repair and replacement services when issues develop due to fabrication defects. We maintain detailed fabrication records to support warranty service throughout the coverage period.

Our 48-hour turnaround commitment on most metal flashing orders reflects our substantial investment in fabrication equipment and skilled craftsmen. We combine traditional metalworking expertise with modern fabrication technology to create custom solutions that other fabricators cannot match. Our engineering knowledge allows us to address complex water management problems that require more than standard flashing solutions.

We implement comprehensive quality control procedures throughout our fabrication process, including material inspection, dimensional verification, and final testing. Our quality standards exceed industry requirements and reflect our BBB A+ rating. Each fabricated component undergoes thorough inspection to ensure it meets specifications and performance requirements before delivery.

We sincerely appreciate your business and the trust you've placed in us for your roofing and custom metal fabrication needs. We believe the highest compliment is a referral, and our Customer Referral Program is our way of saying thank you for sharing your positive experience with friends, family, and neighbors.

Refer a friend, family member, or neighbor to Calebs, and you'll earn a reward when they complete a new roofing or metal fabrication project.

Once their project is successfully completed, you'll be able to choose from a selection of great reward options as our thank you for your referral.

Our program offers increasing rewards based on the number of successful referrals you make. The more you refer, the more you earn!

Your referrals are important to us and truly help us continue to grow our over 40-year legacy so we can serve the Colorado community with excellence!

Ready to protect your Denver property with precision-fabricated sheet metal flashing designed for Colorado's demanding conditions? Calebs Management Enterprises brings 40+ years of experience and a BBB A+ rating to every custom fabrication project.

Our 48-hour turnaround capability on most flashing orders ensures your project stays on schedule, while our engineering expertise delivers solutions for even the most challenging roof configurations. Contact us today to discuss your custom flashing requirements and discover why Denver area contractors consistently choose us for their most demanding sheet metal flashing needs.