When your Denver home features unique architectural elements like bay windows, turrets, or cupolas, you need specialized metal fabrication expertise to protect and enhance these distinctive roof structures. At Calebs Management Enterprises, we've spent over 40 years perfecting our craft as Colorado's premier custom metal fabrication company, specializing in creating and installing the complex flashing systems and protective metalwork that these specialized roof structures require.

We understand that bay windows, turrets, and cupolas aren't just functional elements – they're architectural focal points that define your home's character and curb appeal. Our team combines decades of hands-on experience with precision metalworking techniques to fabricate custom solutions that protect these structures from Colorado's challenging weather while enhancing their aesthetic impact. As BBB A+ rated contractors and proud members of the Colorado Roofing Association, we bring professional standards and craftsmanship excellence to every specialized roof structure project.

Bay windows, turrets, and cupolas represent some of the most challenging roof structure applications in residential construction. These architectural features extend beyond the main roofline, creating complex intersections where water management becomes critical. We've learned through our 40+ years in business that each of these structures demands specific fabrication approaches to ensure long-term protection and performance.

Bay windows project outward from the main structure, creating multiple roof planes that intersect at varying angles. The metal fabrication requirements for bay window roofing include custom-formed cap flashing, step flashing integration, and specialized drainage solutions. We fabricate each piece to match the exact geometry of your bay window, ensuring water flows away from vulnerable joints and intersections.

Turrets and cupolas present even more complex challenges due to their curved or multi-sided geometries. Our fabrication process for these structures involves creating custom-formed metal pieces that follow the unique contours of each architectural element. Whether your turret features a conical roof or your cupola has multiple faceted sides, we have the metalworking expertise to create protective systems that maintain structural integrity while preserving architectural beauty.

Ready to protect and enhance your home's specialized roof structures? Contact us today to discuss your bay window, turret, or cupola project requirements.

Our 40+ years of experience with specialized roof structures has led us to develop advanced fabrication techniques that address the unique challenges presented by bay windows, turrets, and cupolas. These methods combine traditional metalworking skills with modern technology to achieve precision results that stand up to Colorado's demanding weather conditions.

Our fabrication process begins with detailed field measurements of your bay window structure, documenting every angle, dimension, and intersection point that will influence our custom metalwork design.

We fabricate bay window cap flashing systems using high-grade materials selected for durability and weather resistance. The cap flashing forms the primary weather barrier across the top of your bay window roof, and we custom-form each piece to match the exact pitch and dimensions of your specific installation.

We create step flashing systems that integrate seamlessly with your main roof structure while providing complete protection for the bay window walls. Each step flashing piece is individually formed to follow the roof line while maintaining proper overlap with the wall flashing below.

We fabricate custom guttering systems and drainage channels that collect water from bay window roofs and direct it away from your home's foundation. Our metalworking techniques allow us to create seamless transitions between bay window drainage systems and your main roof guttering.

Turret structures present unique fabrication challenges that showcase our advanced metalworking capabilities. These distinctive architectural features require custom-formed metal solutions that follow curved or multi-faceted geometries.

We use custom forming dies and hand-forming methods to shape metal panels that follow the exact curvature of your turret structure. Each panel is fabricated to precise dimensions with careful attention to expansion joint requirements and thermal movement considerations.

We fabricate each panel individually, ensuring proper angles and dimensions for tight-fitting assemblies. Our corner treatment methods eliminate potential water infiltration points while creating visually appealing transition details.

We create custom caps that crown turret structures while providing effective weather sealing. Whether your turret requires a simple flat cap or an elaborate decorative finial, our fabrication capabilities can accommodate any design requirement.

Cupola structures combine architectural beauty with functional requirements, often serving as ventilation systems while adding distinctive visual appeal to residential rooflines.

We can also integrate lightning rod systems and grounding connections into our custom fabrication, ensuring your cupola remains protected from electrical storms while maintaining its architectural appearance.

Template development forms the foundation of our complex geometry fabrication process. We create detailed templates for each project using field measurements and architectural drawings. These templates guide our forming operations and ensure consistent results across multiple fabrication pieces. Our template library includes solutions for common architectural styles while accommodating unique custom requirements.

Progressive forming techniques allow us to create complex curved surfaces without stress concentrations or material thinning. We use specialized forming dies and incremental bending processes to achieve smooth curves and precise angles. This approach ensures structural integrity while maintaining the aesthetic qualities essential to specialized roof structures.

Soldering and seaming expertise enables us to create watertight connections in challenging geometric configurations. Our craftsmen use time-tested joining techniques that provide long-term reliability in demanding applications. We select appropriate soldering materials and techniques based on metal types, environmental exposure, and structural requirements.

Quality control processes ensure every fabricated piece meets our exacting standards before leaving our shop. We test-fit components whenever possible and conduct thorough inspections of all joints, seams, and finished surfaces. Our quality standards reflect our BBB A+ rating and our commitment to delivering fabrication excellence.

Custom tooling development allows us to tackle unique fabrication challenges that standard metalworking equipment cannot address. When project requirements demand specialized forming operations, we create custom tooling that enables precision results. This capability sets us apart in handling truly unique architectural challenges.

Our BBB A+ rating reflects our commitment to customer satisfaction and project excellence. This rating represents consistent performance across hundreds of specialized roof structure projects. Our Colorado Roofing Association membership demonstrates our commitment to industry standards and continuing education.

Our 48-hour turnaround capability on most metal fabrication orders sets us apart from competitors who require weeks for custom work. This rapid response capability means weather-sensitive projects can proceed without lengthy delays. Our efficient fabrication processes and skilled craftsmen enable us to deliver quality results on accelerated schedules.

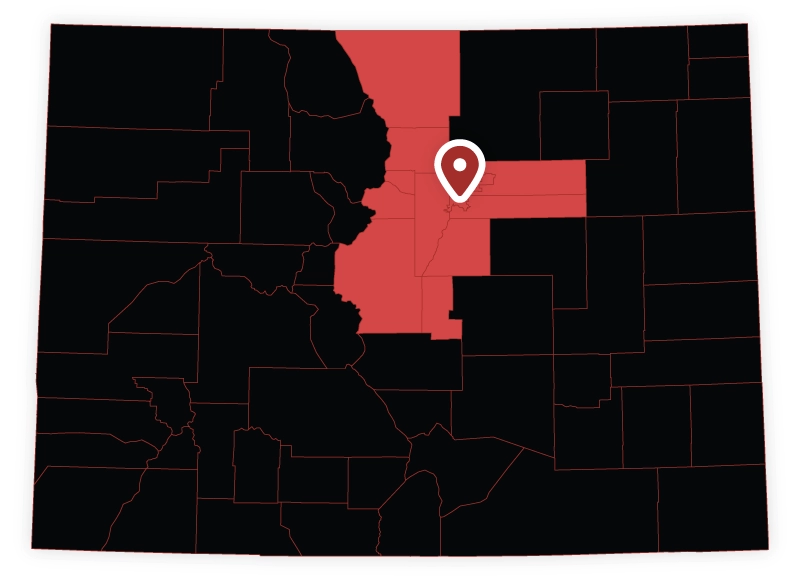

With 40+ years of experience serving the Denver area, we've developed unmatched expertise in specialized roof structure fabrication. Our local knowledge ensures your metalwork performs optimally in Colorado's unique environment. We understand how altitude, temperature extremes, and UV exposure affect different materials and designs.

Note: Calebs installs many roofing systems; the manufacturers shown are those for which Calebs holds certified installer status and can provide a No Dollar Limit (NDL) warranty.

The installation of custom fabricated metalwork for bay windows, turrets, and cupolas requires specialized expertise that goes beyond standard roofing techniques. Our installation teams combine our 40+ years of field experience with precise attention to detail, ensuring every custom fabricated piece performs exactly as designed.

Pre-installation planning becomes critical for specialized roof structure projects. We conduct detailed site surveys before beginning fabrication, documenting existing conditions and identifying potential installation challenges. This planning process allows us to coordinate our custom fabrication with installation requirements.

Our precision fitting techniques ensure our custom fabricated pieces integrate perfectly with existing roof structures. We use specialized measuring tools and fitting methods to achieve tight tolerances and professional appearances.

Our Colorado Roofing Association membership and specialized fabrication capabilities provide additional assurance of craftsmanship and adherence to industry best practices on every specialized roof structure project.

Our standard fabrication turnaround is 48 hours for most specialized roof structure metalwork, significantly faster than industry averages. Complex projects requiring extensive custom forming or multiple components may require additional time, but we provide accurate timelines during initial consultation. Our efficient fabrication processes and skilled craftsmen enable rapid turnaround without compromising quality.

Material selection depends on specific application requirements, architectural style, and performance objectives. Copper provides exceptional longevity and develops attractive patina over time. Galvanized steel offers excellent value with reliable performance. Aluminum provides lightweight solutions for load-sensitive applications. We recommend materials based on your specific project requirements and budget considerations.

Yes, our custom fabrication capabilities allow us to match virtually any architectural style or finish requirement. We can replicate historical details, match existing metalwork, or create entirely new designs that complement your home's character. Our 40+ years of experience with diverse architectural styles enables us to achieve authentic results for any design challenge.

We provide comprehensive warranties covering both fabrication quality and installation workmanship. Warranty terms vary based on materials and application requirements, but all our work is backed by our commitment to customer satisfaction. Our BBB A+ rating and 40+ years in business demonstrate our ability to stand behind our warranty commitments.

Permit requirements vary based on project scope and local building code requirements. Minor repairs typically don't require permits, while major modifications or new installations often do. We assist with permit applications when necessary and ensure all our work meets applicable building codes and standards.

We approach repairs for specialized roof structures with comprehensive assessment and custom fabrication solutions. Our 48-hour fabrication capability ensures timely replacement components, and we prioritize efficient scheduling to minimize weather exposure. Contact our office to schedule an assessment if your bay window, turret, or cupola needs repair or replacement components.

We recommend annual inspections for most specialized roof structure installations, with additional inspections after severe weather events. Our inspection protocols focus on critical areas where problems typically develop first. We provide specific guidance for different materials and finishes, ensuring your maintenance efforts enhance rather than damage protective coatings.

The key to successful specialized roof structure protection lies in understanding how water behaves around these complex geometries. We approach each project by analyzing the specific water flow patterns around your structure, then designing custom metal solutions that channel moisture away from vulnerable areas. Our fabrication techniques ensure proper overlap sequences and create clean, professional appearances.

We sincerely appreciate your business and the trust you've placed in us for your roofing and custom metal fabrication needs. We believe the highest compliment is a referral, and our Customer Referral Program is our way of saying thank you for sharing your positive experience with friends, family, and neighbors.

Refer a friend, family member, or neighbor to Calebs, and you'll earn a reward when they complete a new roofing or metal fabrication project.

Once their project is successfully completed, you'll be able to choose from a selection of great reward options as our thank you for your referral.

Our program offers increasing rewards based on the number of successful referrals you make. The more you refer, the more you earn!

Your referrals are important to us and truly help us continue to grow our over 40-year legacy so we can serve the Colorado community with excellence!

When you choose Calebs Management Enterprises, Inc., you're selecting a contractor with 40+ years of proven expertise throughout Denver, Colorado. Our specialized roof structure fabrication services provide the complete solution for property owners with bay windows, turrets, and cupolas who demand both quality and reliability.

Our BBB A+ rating, Colorado Roofing Association membership, and unique 48-hour turnaround capability on custom metal fabrication deliver responsive service and superior craftsmanship. Ready to protect and enhance your home's specialized roof structures with custom metal fabrication excellence? Contact us today.